Dichtol is the advanced sealing system engineered to eliminate microporosity in additive manufacturing (3D printing), metal casting defects, and thermal spray coatings. Its unique formulation ensures:

Deep Penetration into Microporosity

Thanks to exceptional capillary action, Dichtol penetrates pores from 0.1 mm up to 0.5 mm, reaching even the most complex internal structures.

Thermal and Chemical Resistance

Ideal for demanding environments, Dichtol withstands continuous temperatures up to +700°C and exposure to aggressive chemicals.

Multi-Material Compatibility

Dichtol adheres effectively to metals, polymers, and Thermal Spray coatings, making it the perfect solution for a wide range of industrial sectors..

Reliable for 3D Printed Parts

Prevent leakage, delamination, or porosity issues in additive manufactured parts. Dichtol improves mechanical integrity and post-processing performance.

Gas and Fluid Tightness

Dichtol creates a durable barrier against gas and liquid leakage – essential in pressure-loaded or high-performance components.

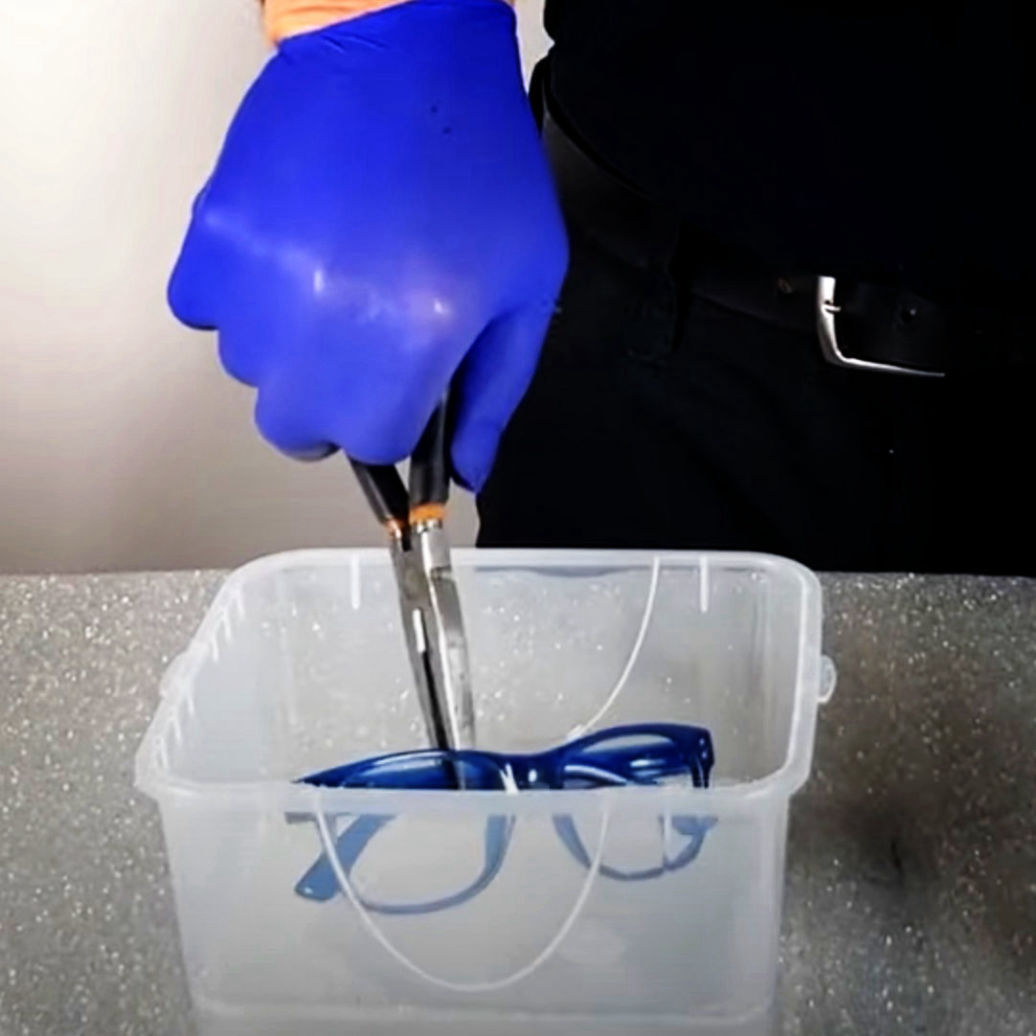

Adaptable Application Methods

Apply by brushing, spraying, immersion, or injection – fast, simple, and cost-effective, even on large or complex surfaces.

Sealing of Functional Components

Essential to enhance the strength and reliability of 3D printed parts, especially in critical industrial applications.

Repair of Porosity and Micro-Cracks

Effectively seals internal defects without altering the geometry or dimensions of the component.

Surface Preparation for Painting or Coating

Creates a smooth, sealed surface ideal for paint or surface treatments, improving coating adhesion and final finish quality.

Dichtol is designed to deeply impregnate and seal pores up to 0.5 mm, even in complex structures. Developed to meet the demands of the automotive and foundry industries, it delivers exceptional thermal and chemical resistance, ensuring long-lasting performance under extreme conditions.

By significantly reducing scrap rates, Dichtol plays a vital role in improving production profitability. As a key element of modern quality control in foundry and manufacturing processes, it ensures consistent high-quality results while minimizing operational costs.

When porosity is detected or remains stable in serial production, Dichtol offers a fast, targeted sealing alternative. Unlike costly vacuum impregnation systems, Dichtol requires no large-scale equipment, making it ideal for localized and economical repairs.

Why Choose Dichtol?

Choosing Dichtol means relying on a tested and certified solution that guarantees:

High performance in demanding industrial environments

Long-lasting durability and reliability

Dedicated technical support from AMU Princigalli

Strada delle Brigole 3/A, 23877 Paderno D'Adda

8:30 - 17:00